Optimization of concrete produced from industrial waste and fibre using regresion model

Keywords:

Industrial Waste, Concrete, Optimization, regresion model, glass fiberAbstract

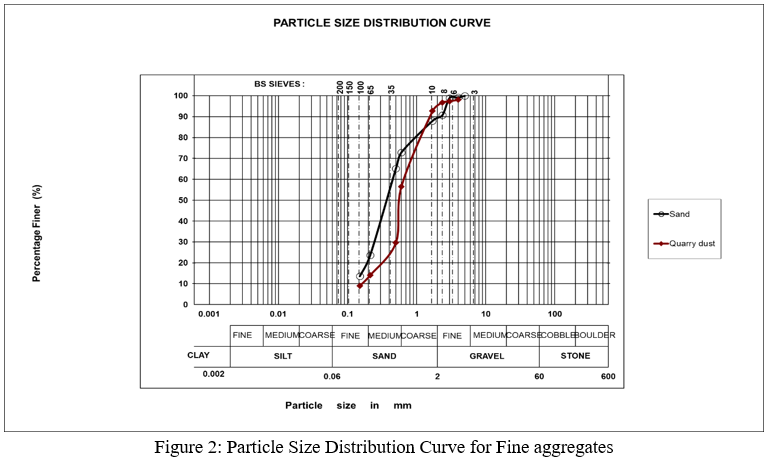

This research examined the potential for reusing glass fiber, fly-ash, and quarry dust, in concrete production through partial substitution of traditional cement and sand. The study employed an experimental mix design to ascertain the compressive strength of concrete when these waste materials are incorporated. Various tests, including compressive strength, slump, and air void tests, were conducted on concrete cube samples with varying percentages of waste material substitutions. The cube samples were designed with specific proportions: fly-ash replaced cement at increments of 10%, 20%, and 30%, while glass fibers were added as an admixture at 1%, 2%, and 3%. Similarly, quarry dust replaced sand at 10%, 20%, and 30%, with glass fibers added at the same percentages. Additional cube samples were prepared with quarry dust and fly ash partially replacing sand and cement at 5%, 10%, and 15%, with glass fibers added at 1%, 2%, and 3%. These samples were subjected to a curing process in water for durations of 7, 14, 21, and 28 days. A linear regression model was developed based on forty compressive strength test results, positioning compressive strength as the dependent variable and the volume of glass fibers, quarry dust and fly ash as independent variables. A model of the form: CS = 0.216Vgf + 0.068Vqd + 0.979Vfa + 26.078 was developed where CS is the compressive strength, while Vgf, Vqd and Vfa represent volume of glass fibers, quarry dust and fly ash with their coefficients respectively. The model's findings indicate that the industrial waste that significantly enhances the compressive strength of the concrete is fly ash, followed by glass fibers, while quarry dust has minimal influence. The optimal strength achieved was 24.89 N/mm2 at 28 days when fly-ash, quarry dust, and glass fibers were combined.

Downloads

References

D. Tavakoli, A. Heidari, and B. Behfrouz, "Using waste materials in cement and concrete way towards sustainable development," presented at the First International Cement Industry, Energy and Environment Conference, Tehran University, Iran, 2012.

C. Arum, C. M. Ikumapayi, and G. O. Aralepo, "Ashes of biogenic wastes-pozzolanicity, prospects for use, and effects on some engineering properties of concrete," 2013.

Y. Wang et al., "Concrete reinforcement with recycled fibers," Journal of Materials in Civil Engineering, 2000.

S. K. Antiohos, V. G. Papadakis, and S. Tsimas, "Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness," Cement and Concrete Research, vol. 61, pp. 20-27, 2014.

A. Anandamurthy, V. Guna, M. Ilangovan, and N. Reedy, "A review of fibrous reinforcements of concrete," Journal of Reinforced Plastics and Composites, vol. 519, pp. 552, 2017.

N. Ay and M. Unal, "The use of waste ground ceramic in cement production," Cement and Concrete Research, vol. 30, no. 3, pp. 497–499, 2000.

G. Balamurugan and P. Perumal, "Behaviour of concrete on the use of quarry dust to replace sand–an experimental study," International Journal of Engineering Science Invention, vol. 3, no. 6, 2013.

P. Berkowski and K. M. Kosior, "Effect of fiber on the concrete resistance to surface scaling due to cyclic freezing and thawing," Procedia Engineering, pp. 121-127, 2015.

F. Burak, "The effect of fly ash and limestone fillers on the viscousity and compressive strength of self compacting repair mortars," Cement and Concrete Research, pp. 1719-1726, 2006.

J. D. Chaitanya and E. Arunakanthi, "Experimental Studies of Fiber Reinforced Concrete," International Journal of Civil Engineering and Technology, vol. 2987, pp. 2999, 2016.

A. Chatterjee and T. Sui, "Alternative fuels–effects on clinker process and properties," Cement and Concrete Research, vol. 123, p. 105777, 2019.

C. Chen, G. Habert, Y. Bouzidi, and A. Jullien, "Environmental impact of cement production: detail of the different processes and cement plant variability evaluation," Journal of Cleaner Production, vol. 18, no. 5, pp. 478-485, 2010.

C. -H. H. Chung-Ho, S. -k. L. Shu-ken, C. -S. C. Chao-Shun, and H. -J. C. How-Ji, "Mix proportions and mechanical properties of concrete containing very high-volume of class F fly ash," Construction and Building Materials, vol. 71, pp. 78, 2013.

D. Foti, "Use of recycled waste pet bottles fibers for the reinforcement of concrete," Composite Structures, vol. 96, pp. 396-404, 2013.

B. C. Gayana and K. Ram Chandar, "Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements-A review," 2018.

I. Guerra et al., "Eco-efficient concretes: The effects of using recycled ceramic material from sanitary installations on the mechanical properties of concrete," Waste Management, vol. 29, pp. 643–646, 2009.

R. Ilangovan, N. Mahendran, and K. Nagamani, "Strength and durability properties of concrete containing quarry rock dust as fine aggregates," ARPN Journal of Engineering and Applied Sciences, 2008.

G. M. Islam and G. S. Das, "Evaluating plastic shrinkage and permeability of polypropylene fiber reinforced concrete," International Journal of Sustainable Built Environment, vol. 345, pp. 354, 2016.

M. Jawaid and H. P. Abdul Khalil, "Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review," Carbohydrate Polymers, vol. 1, pp. 18, 2011.

R. Kumar et al., "Fast response and recovery of hydrogen sensing in Pd–Pt nanoparticle–graphene composite layers," Nanotechnology, vol. 22, no. 27, p. 275719, 2011.

S. Kumar and R. Kumar, "Mechanical activation of fly ash: Effect on reaction, structure and properties of resulting geopolymer," Ceramics International, vol. 37, no. 2, pp. 533-541, 2011.

H. T. Le and H. M. Ludwig, "Effect of rice husk ash and other mineral admixtures on properties of self-compacting high performance concrete," Materials & Design, vol. 89, pp. 156-166, 2016.

Y. Lei et al., "Primary anthropogenic aerosol emmision trends for china, 1990-2005," Atmospheric Chemistry and Physics, vol. 11, no. 3, pp. 931-954, 2011.

V. Lopez et al., "Eco-efficient concretes: Impact of the use of white ceramic powder on the mechanical properties of concrete," Biosystems Engineering, vol. 96, no. 4, pp. 559–564, 2007.

B. Z. Mahasneh, "The Effect of Addition of Fiber Reinforcement on Fire Resistant Composite Concrete Material," Journal of Applied Sciences, vol. 373, pp. 379, 2005.

C. Medina, P. Banfill, M. S. de Rojas, and M. Frias, "Rheological and calorimetric behaviour of cements blended with containing ceramic sanitary ware and construction/demiltion waste," Construction and Building Materials, vol. 40, pp. 822–831, 2013.

P. K. Mehta and P. J. Monteiro, Concrete: microstructure, properties, and materials. McGraw-Hill Education, 2014.

E. Mello, C. Ribellato, and E. Mohamedelhassan, "Improving Concrete Properties with Fibers Addition," International Scholarly and Scientific Research & Innovation, vol. 245, pp. 250, 2014.

K. Murahari and R. Rao, "Effects ofpolypropylene fibers on the strength properties of fly ash based concrete," International Journal of Engineering Science Invention, vol. 2, no. 5, pp. 13-19, 2013.

K. Portella, A. Joukoski, R. Franck, and R. Derksen, "Secondary recycling of electrical insulator porcelain waste in Portland concrete structures: Determination of the performance under accelerated aging," Ceramica, vol. 52, pp. 155–167, 2006.

G. Sandin, G. M. Peters, and M. Svanström, "Life cycle assessment of construction materials: the influence of assumptions in end-of-life modelling," The International Journal of Life Cycle Assessment, vol. 19, pp. 723-731, 2014.

R. M. K. Saravana and A. Sumathi, "Effects of fly ash in fiber reinforced concrete composites," Jordan Journal of Civil Engineering, vol. 11, no. 1, 2017.

N. Sebaibi, M. Benzerzour, and N. E. Abriak, "Influence of the distribution and orientation of fibers in a reinforced concrete with waste fibers and powders," Construction and Building Materials, vol. 65, pp. 254D.

Downloads

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2024 Funminiyi Oyekunle, Prof. B. D. Oluyemi-Ayibiowu, Adeola Akinsuyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any article in the International Journal of Engineering and Applied Physics is retained by the author(s) under the Creative Commons license, which permits unrestricted use, distribution, and reproduction provided the original work is properly cited.

License agreement

Authors grant IJEAP a license to publish the article and identify IJEAP as the original publisher.

Authors also grant any third party the right to use, distribute and reproduce the article in any medium, provided the original work is properly cited.

Most read articles by the same author(s)

- Funminiyi Oyekunle, Sanya OGUNSUSI, E.O. Aiyewalehinmi, Kunle AMOKO, Assessment of occupational health and safety risks in selected construction sites in oyo state, Nigeria , International Journal of Engineering and Applied Physics: Vol. 5 No. 1: January 2025

- IJANUSI Ebenezer Oluwafemi, AIYEWALEHINMI E. O., Funminiyi Oyekunle, ODOFIN Sunday Festus, Evaluation of production cost of bricks using clay and stone dust-cement , International Journal of Engineering and Applied Physics: Vol. 5 No. 2: May 2025