Optimizing Green Concrete Brick Production with Rice Husk and Glass Waste: A Path to Sustainable Building

Keywords:

Composite Bricks, Compressive Stregnth, Rice Husk, Glass Powder, Sustainable EnvironmentAbstract

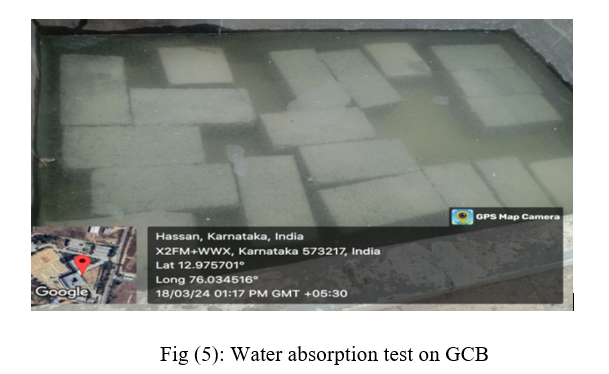

This study investigates the performance of green composite cement bricks (GCB) incorporating waste glass powder and rice straw additives by conducting a series of compression tests across five distinct mixes (Mix A through Mix E). Each mix varied in the percentage composition of waste glass powder (ranging from 5% to 25%) and rice straw (ranging from 10% to 50%). A total of 15 bricks were cast to evaluate their compressive strength over different curing periods.The compression tests were performed at 7 days, 14 days, and 28 days of curing to assess the development of compressive strength over time. The results for each mix were analyzed to determine the impact of varying compositions on the bricks' structural performance. Additionally, compression tests were also conducted on conventional bricks, which are not standardized in size and whose dimensions vary by region. Conventional bricks typically have lengths ranging from 210 mm to 250 mm, widths from 100 mm to 130 mm, and thicknesses from 70 mm to 100 mm.The findings from this study provide valuable insights into the feasibility of using green composite bricks as a sustainable construction material, highlighting their compressive strength performance compared to conventional bricks and demonstrating the effectiveness of incorporating waste materials in enhancing brick properties.

Downloads

References

Reddy, B. V., & Reddy, N. S. (2023). Utilization of Waste Glass Powder in Concrete: A Review. Journal of Cleaner Production, 367, 133179. https://doi.org/10.1016/j.jclepro.2022.133179

Hossain, K. M. A., & Islam, M. R. (2022). Reuse of Agricultural Residues in Brick Production: An Overview of Recent Advancements. Construction and Building Materials, 326, 126734. https://doi.org/10.1016/j.conbuildmat.2022.126734

Chen, H., Zhang, L., & Liu, Y. (2022). Incorporation of Waste Glass in Cement-Based Materials: An Overview. Journal of Sustainable Cement-Based Materials, 11(1), 26-48. https://doi.org/10.1080/21650373.2022.2010001

Gomez-Soberon, J. M., & Sanchez, M. (2022). Green Bricks from Waste Glass and Fly Ash: A Sustainable Approach. Materials, 15(6), 1884. https://doi.org/10.3390/ma15061884

Arulraj, G., & Kumar, S. (2023). Rice Straw Ash as a Partial Replacement for Cement in Concrete: A Review. Construction and Building Materials, 372, 131904. https://doi.org/10.1016/j.conbuildmat.2022.131904

Siddique, R., & Kumar, S. (2022). Green Concrete: Properties, Applications, and Future Directions. Journal of Building Engineering, 44, 103555. https://doi.org/10.1016/j.jobe.2021.103555

Zhu, S., Chen, B., & Liu, J. (2023). Sustainable Concrete Production with Recycled Materials: A Review. Resources, Conservation & Recycling, 186, 106573. https://doi.org/10.1016/j.resconrec.2022.106573

Khan, M. N., & Khan, M. A. (2023). Feasibility of Using Waste Glass Powder in Brick Manufacturing: An Experimental Study. Journal of Materials in Civil Engineering, 35(5), 04023033. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004255

Memon, S. A., & Memon, R. A. (2022). Rice Straw Ash in Cement-Based Materials: A Comprehensive Review. Journal of Environmental Management, 306, 114423. https://doi.org/10.1016/j.jenvman.2022.114423

Javed, M. F., & Ali, U. (2022). Waste Glass Powder and Its Utilization in Cement and Concrete: A Review. Advances in Civil Engineering, 2022, 3497804. https://doi.org/10.1155/2022/3497804

Nagarajan, R., & Suresh, K. (2023). Performance Evaluation of Composite Bricks Using Agricultural Waste. Sustainable Materials and Technologies, 43, 102855. https://doi.org/10.1016/j.susmat.2022.102855

Jang, J. G., & Kim, H. S. (2022). Impact of Waste Materials on the Mechanical Properties of Green Bricks. Construction and Building Materials, 328, 126986. https://doi.org/10.1016/j.conbuildmat.2022.126986

Al-Wahaibi, Y. M., & Al-Kharusi, L. M. (2022). Innovative Uses of Recycled Materials in Brick Production: A Review. Journal of Environmental Chemical Engineering, 10(2), 108580. https://doi.org/10.1016/j.jece.2021.108580

Singh, M., & Singh, S. P. (2022). Green Bricks: Production, Properties, and Sustainability Aspects. Building and Environment, 208, 108610. https://doi.org/10.1016/j.buildenv.2021.108610

Kumar, V., & Singh, R. P. (2023). Sustainable Bricks: Utilization of Waste Materials for Eco-Friendly Construction. Construction and Building Materials, 375, 131814. https://doi.org/10.1016/j.conbuildmat.2022.131814

Downloads

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2024 Ms.Bandhavya G B Gowda, Prashath S, Sandeep K, Bindhushree G B

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any article in the International Journal of Engineering and Applied Physics is retained by the author(s) under the Creative Commons license, which permits unrestricted use, distribution, and reproduction provided the original work is properly cited.

License agreement

Authors grant IJEAP a license to publish the article and identify IJEAP as the original publisher.

Authors also grant any third party the right to use, distribute and reproduce the article in any medium, provided the original work is properly cited.

Most read articles by the same author(s)

- Ms.Bandhavya G B Gowda, Influence of River Water and Treated Industrial Sewage Water Quality on Compressive Strength of Concrete with Sawdust Ash as Partial Replacement of Cement , International Journal of Engineering and Applied Physics: Vol. 2 No. 3: September 2022

- Ms.Bandhavya G B Gowda, An Influence of Recycled Concrete Aggregate and Treated Waste Water Containing 50% GGBS Content in Light weight Concrete Mixes , International Journal of Engineering and Applied Physics: Vol. 4 No. 1: January 2024