Characterization of mechanical properties of bamboo fiber-reinforced epoxy composites

Keywords:

Bamboo Fiber, Mechanical Properties, Epoxy Composites, Tensile Strength, Flexural Strength, Impact StrengthAbstract

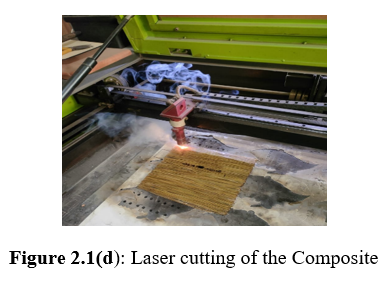

This research investigates the mechanical properties of bamboo fiber-reinforced unidirectional epoxy composites, focusing on two bamboo species, Bambusa Vulgaris (Baijja bamboo) and Melocanna Baccifera (Mulli bamboo). The study examines the tensile, flexural, and impact properties of composites fabricated from bamboo fibers extracted from different sections (top, middle, bottom) of the bamboo culm. The composites were prepared using a hand layup method and subjected to mechanical testing according to ASTM standards. Results show that the middle portion of both bamboo species exhibits superior mechanical performance compared to the top and bottom portions. Specifically, the middle section demonstrates higher tensile strength, tensile modulus, flexural strength, flexural modulus, and impact strength. The enhanced properties of the middle section are attributed to factors such as fiber alignment, density, and composition. The findings suggest that utilizing bamboo fibers from the middle portion can lead to the development of high-quality composite materials suitable for various engineering applications, particularly in automotive part manufacturing. This research underscores the importance of understanding the mechanical behavior of bamboo composites for optimizing their use in sustainable and eco-friendly industrial products.

Downloads

References

I. Elfaleh et al., “A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials,” Results Eng., vol. 19, no. June, p. 101271, 2023, doi: 10.1016/j.rineng.2023.101271.

P. Zakikhani, R. Zahari, M. T. H. Sultan, and D. L. Majid, “Extraction and preparation of bamboo fibre-reinforced composites,” Mater. Des., vol. 63, pp. 820–828, 2014, doi: 10.1016/j.matdes.2014.06.058.

A. Biswas, M. Rahman, I. U. Bhuiyan, M. Mashuk, and M. Moula, “Optimizing Weight Fractions and Chemical Treatments to Increase the Shore Hardness of Woven E-Glass, Woven Jute, and Kenaf Hybrid Composite Laminates,” no. April, 2024, doi: 10.46254/ba06.20230022.

P. Lokesh, T. S. A. Surya Kumari, R. Gopi, and G. B. Loganathan, “A study on mechanical properties of bamboo fiber reinforced polymer composite,” Mater. Today Proc., vol. 22, no. December 2019, pp. 897–903, 2020, doi: 10.1016/j.matpr.2019.11.100.

S. A. H. Roslan, Z. A. Rasid, and M. Z. Hassan, “Bamboo reinforced polymer composite - A comprehensive review,” IOP Conf. Ser. Mater. Sci. Eng., vol. 344, no. 1, 2018, doi: 10.1088/1757-899X/344/1/012008.

F. Albermani, G. Y. Goh, and S. L. Chan, “Lightweight bamboo double layer grid system,” Eng. Struct., vol. 29, no. 7, pp. 1499–1506, 2007, doi: 10.1016/j.engstruct.2006.09.003.

G. Cantero, A. Arbelaiz, R. Llano-Ponte, and I. Mondragon, “Effects of fibre treatment on wettability and mechanical behaviour of flax/polypropylene composites,” Compos. Sci. Technol., vol. 63, no. 9, pp. 1247–1254, 2003, doi: 10.1016/S0266-3538(03)00094-0.

D. Awalluddin et al., “Mechanical properties of different bamboo species,” MATEC Web Conf., vol. 138, pp. 1–10, 2017, doi: 10.1051/matecconf/201713801024.

S. Bhatia, S. Angra, and S. Khan, “Mechanical and wear properties of epoxy matrix composite reinforced with varying ratios of solid glass microspheres,” J. Phys. Conf. Ser., vol. 1240, no. 1, 2019, doi: 10.1088/1742-6596/1240/1/012080.

M. P. Ho et al., “Critical factors on manufacturing processes of natural fibre composites,” Compos. Part B Eng., vol. 43, no. 8, pp. 3549–3562, 2012, doi: 10.1016/j.compositesb.2011.10.001.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Md. Iftekhar Alam, Raihanuzzaman, Khalid Bin Sayeed, Md Shahnewaz Bhuiyan, Md. Kharshiduzzaman

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any article in the International Journal of Engineering and Applied Physics is retained by the author(s) under the Creative Commons license, which permits unrestricted use, distribution, and reproduction provided the original work is properly cited.

License agreement

Authors grant IJEAP a license to publish the article and identify IJEAP as the original publisher.

Authors also grant any third party the right to use, distribute and reproduce the article in any medium, provided the original work is properly cited.