Maintenance strategy focused on the specific consumption of diesel generators in sub-saharan countries: Case of National Electricity Company of Burkina Faso

Keywords:

Diesel thermal power plant, Specific consumption, Predictive maintenance, Burkina FasoAbstract

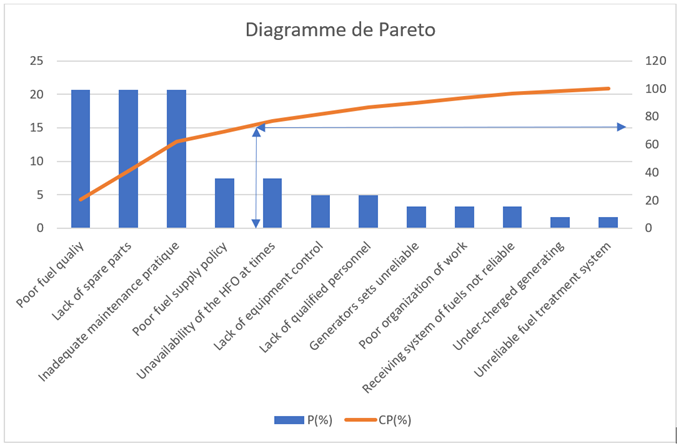

Sub-Saharan countries would mainly use thermal power plant whose Specific Consumption (SC) was relatively higher than the reference values provided by the manufacturers, which would contribute to the increase in electricity production costs. The aim of this study would be to propose a maintenance strategy which would aim to keep the SC according to the age of the generator at acceptable proportions according to the reference values provided by the manufacturers. The Ishikawa and Pareto diagrams were used to identify and analyze the causes of the variation in the SC of two large plants of the National Electricity Company of Burkina Faso. The results showed four major causes representing about 20% of the common causes which are 80% of the increase in SC in the thermal power plant of Kossodo and Komsilga, it would be : the poor quality of the fuels, lack of spare parts, inadequate maintenance practice, and poor fuel supply policy.

Downloads

References

Anon. (2018a). Energy Strategy 2019-2023. Ministry of Energy of Burkina Faso.

Anon. (2018b). Energy Strategy 2019-2023. Ministry of Energy of Burkina Faso.

Anon. (2014c). CATERPILLAR VM43C. Long-stroke diesel engines for maximum efficiency and high reliability 12. 16 cylinders.

Anon. (2020d). http://compressor.cmc-mtu.com/index.php/tag/man-18-v-4860-b-diesel-engine-weight/, MAN B&W 18V48/60B diesel engine and generator, date accessed 03/31/2020.

Anon. (2020e). https://www.wartsila.com/docs/default-source/product-files/engines/ms-engine/product- guide-, accessed 03/31/2020.

Anon. (2020f). https://www. quantiparts.com /deutz-D640.pdf.

A. Marjanovi?, G. Kvaš?ev, P. Tadi?, and Ž. DJurovi?, “Applications of predictive maintenance techniques in industrial systems,” Serbian Journal of Electrical Engineering, vol. 8, no. 3, p. 263,279, 2011.

A. Grall, L. Dieulle, C. Berenguer, and M. Roussignol, Continous-time predictive maintenance scheduling for a deteriorating system, IEEE Transactions on Reliability (51/2), pp. 141-150, 2002.

A. Ouédraogo and A.G. Sodre, “Models for Quantification and Mitigation of Atmospheric Releases from Diesel Power Plants”, p. 77, 2006.

Y. Fatoumata, A. Amor, “Machine learning for predictive maintenance,” 85.

Francastel, J.C. (2003). Maintenance Engineering, Dunod Edition, Paris.

B. Houessou, “Development of an Opportunity Analysis Package for the Implementation of a Solution Enhancing Existing GMAO Systems,” 2015. Ecole de technologie supérieure du Québec, Canada.

G. Sullivan, R. Pugh, A. P. Melendez, and W. D. Hunt, “Operations & Maintenance Best Practices - A Guide to Achieving Operational Efficiency (Release 3),” Pacific Northwest National Lab. (PNNL), Richland, WA (United States), PNNL-1963

I.Taztaz, « Artificial Intelligence applied to predictive maintenance of inverters », p. 59.

K. E. Mckone et E. N. Weiss, « Guidelines for Implementing Predictive Maintenance* », Production and Operations Management, vol. 11, no 2, p. 109 124, 2002, doi : 10.1111/j.1937-5956.2002.tb00486.x.

L. Lu et J. Jiang, Analysis of on-line maintenance strategies for k-out-of-n standby safety systems, Reliability Engineering and System Safety (92), pp. 144-155, 2007.

L.M. Maillart et S. M. Pollock, Cost-optimal condition-monitoring for predictive maintenance of 2-phase systems, IEEE Transaction on Reliability (51/3), pp. 322-330, 2002.

L.R. Contreras, C. Modi, et A. Pennathur, Integrating simulation modeling and equipment condition diagnostics for predictive maintenance strategies. a case study, In Winter Simulation Conference, pp. 1289-1294, 2002.

L. G. D. M’bama Nzaou, « Determination of the optimal placement scale of the production sources of the interconnected network in Burkina Faso by the method of kuhn-tucker », 2019.

M. Crowder et J. Lawless, On a scheme for predictive maintenance, European Journal of Operational Research (176), pp. 1713-1722, 2007.

M. C. Eti, S. O. T. Ogaji, et S. D. Probert, Reducing the cost of preventive maintenance (pm) through adopting a proactive reliability-focused culture, Applied Energy (83), pp. 1235-1248, 2006.

M.C. Carnero, Selection of diagnostics techniques and instrumentation in a predictive maintenance program. a case study. Decision Support System (91), pp. 945-963, 2003.

M.C. Carnero, An evaluation system of the setting up of predictive maintenance programmes, Reliability Engineering and System Safety, 2006.

M. Dachyar, R. Nurcahyo, et Y. Tohir, « MAINTENANCE STRATEGY SELECTION FOR STEAM POWER PLANT IN RANGE OF CAPACITY 300 - 625 MW IN INDONESIA », vol. 13, no 7, p. 10, 2018.

« Maintenance-Methods and organizations-François Monchy-Librairie Eyrolles ». https://www.eyrolles.com/Entreprise/Livre/maintenance-9782100078165/ (accessed March 9, 2022).

« Predictive Maintenance : Definition and Industry Interest ». https://www.journaldunet.fr/web-tech/dictionnaire-de-l-iot/1489507-maintenance-predictive-definition-et-interet-dans-l-industrie/ (accessed March 9, 2022).

« Memoire Online - Industrial energy audit on the Contourglobal-Togo-SA tri-fuel thermal power plant - KoétAgbà lénkoNIKOUEGAN », MemoireOnline. https://www.memoireonline.com/05/12/5883/m_Audit-energetique-industriel-sur-la-centrale-thermique-tri-fuel-de-Contourglobal-Togo-SA12.html (accessed January 6, 2022).

O. O. Shopeju et S. O. Oyedepo, « A Comprehensive Review of Thermal Power Plants Reliability Using Stochastic Methods », in IOP Conference Series : Materials Science and Engineering, 2021, vol. 1107, no 1, p. 012161.

P.-X. Thivel, P. Hus, M. Depriester, et F. Rougeot, « Diagnostic maintenance of a stationery waste water treatment plant », waste-sciences-techniques, vol. 34, p. 27 35, 2004, doi : 10.4267/waste-sciences-techniques

R.J. Murry et B.F. Mitchell, Cost saving from a practical predictive maintenance program, In Annual Reliability and Maintainability Symposium, pp. 206-209, 1994.

X. Zhou, L. Xi, et J. Lee, Reliability-centered predictive maintenance scheduling for a continuously monitored system subject to degradation, Reliability Engineering and System Safety (92), pp. 530_534, 2007.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Alain ILBOUDO, Frederic Bationo

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any article in the International Journal of Engineering and Applied Physics is retained by the author(s) under the Creative Commons license, which permits unrestricted use, distribution, and reproduction provided the original work is properly cited.

License agreement

Authors grant IJEAP a license to publish the article and identify IJEAP as the original publisher.

Authors also grant any third party the right to use, distribute and reproduce the article in any medium, provided the original work is properly cited.