Biogas production according to the waste categories

Keywords:

Biogas, Methanization, Kinetic, Simulation, MatlabAbstract

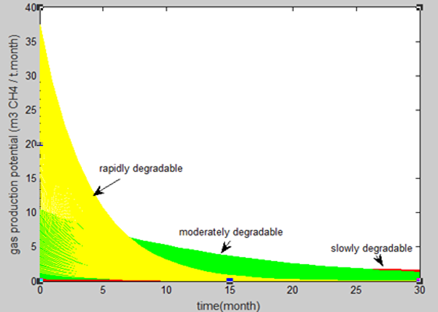

The aim of the present work is to model the production of a biogas according to the different categories of the biodegradable materials. The simulation model that predicts biogas production from a plug-flow anaerobic digester is developed. This model is based on the kinetic equation of the methanization. A first-order kinetic model is used to predict the chemical reactions in the digestion process. A model prediction is validated against Numerical simulation measured biogas production and data which are obtained from the literature.

Downloads

References

Buswell, A.M. ; Muller, H.F. Mechanisms of methane fermentation, Industrial Engineering Chemistry, 1962,44,550.

Robert,B. ; Ana, S.; Josip, P.; Lidija, C.; Boris, C.; Tomislav P.; Neven, D. Opportunities and challenges: Experimental and kinetic analysis of anaerobic co-digestion of food waste and rendering industry streams for biogas production. Renewable and Sustainable Energy Reviews. 2020, 130, 109951, https://doi.org/10.1016/j.rser.2020.109951.

Vinod, K.; Pankaj, K.; Piyush K.; Jogendra, S. Anaerobic digestion of Azolla pinnata biomass grown in integrated industrial effluent for enhanced biogas production and COD reduction: Optimization and kinetics studies. Environmental Technology & Innovation Environmental Technology & Innovation, 2020, 17, 100627, https://doi.org/10.1016/j.eti.2020.100627.

Agata, G.; Camilla, M.B., Andrea, G.; Daniele M.; Pamela, P.K. waste valorization through a mild-temperature pretreatment to enhance biogas production and fermentability: Kinetics study in mesophilic and thermophilic regimen. Journal of Environmental Sciences. 2020, 89, 167-179, https://doi.org/10.1016/j.jes.2019.10.016.

Sagarika, P.H.; Bhakta, S.; Brajesh, K.D. Anaerobic co-digestion of food waste with pretreated yard waste: A comparative study of methane production, kinetic modeling and energy balance. Journal of Cleaner Production. 2020 , 243, 10, 118480, https://doi.org/10.1016/j.jclepro.2019.118480.

Minott, S.J.; Scott, N.R. Feasibility of Fuel Cells for Biogas Energy Conversion on Dairy Farms. American Society of Agricultural and Biological Engineers, 2001, 017015, doi: 10.13031/2013.7508

Hossain, M.; Zabed, S.A.; Junhua, Y.; Guoyan Zhang, Y.Z.; Xianghui, Q. Biogas from microalgae: Technologies, challenges and opportunities. Renewable and Sustainable Energy Reviews. 2020,117, 109503, https://doi.org/10.1016/j.rser.2019.109503.

Halil, ?.; Ünsal, A.; Serkan, D.; Volkan, O. Anaerobic digestion of cattle manure, corn silage and sugar beet pulp mixtures after thermal pretreatment and kinetic modeling study. 2020, 263, 116651, https://doi.org/10.1016/j.fuel.2019.116651.

Bakraoui, M.; El Gnaoui, Y. ; Lahboubi, N. ; Karouach, F.; Hassan El Bari, H. Kinetic study and experimental productions of methane production from UASB reactor treating wastewater from recycled pulp and paper for the continuous test. Biomass and Bioenergy. 2020, 139, 105604, https://doi.org/10.1016/j.biombioe.2020.105604.

Meisam, T.; Mortaza, A.; Valijanianbe, E. ; Kazemi, H.; Panahie, S. ; Nizamif, A.S. ; Ghanavatibc, H.; Alawi, S.; Safoora, M.; Karimigh, K. A comprehensive review on recent biological innovations to improve biogas production, Part 1: Upstream strategies. Renewable Energy. 2020Volume 146, 1204-1220, https://doi.org/10.1016/j.renene.2019.07.037.

Almomani, F.; Bhosale, R.R. Enhancing the production of biogas through anaerobic co-digestion of agricultural waste and chemical pre-treatments. Chemosphere. 2020, 255, 126805. https://doi.org/10.1016/j.chemosphere.2020.126805.

Almomani, F. Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network. Fuel. 2020, 280, 15, 118573, https://doi.org/10.1016/j.fuel.2020.118573.

Ponugotti. P.V. Mechanistic Kinetic Model for Biogas Dry Reforming Ind. Eng. Chem. Res. 2020, 59, 33, 14737–14746,doi.org/10.1021/acs.iecr.0c02433.

Montalvo, S.;Martinez, J.; Castillo A.;C. Huiliñir, C.; Borja R.; Ricardo Salazar R. Sustainable energy for a winery through biogas production and its utilization: A Chilean case study, Sustainable Energy Technologies and Assessments. 2020, 37, 100640, https://doi.org/10.1016/j.seta.2020.100640.

Yanshan, W.; Yihang, L.; Yingxiu, Z.;, Yingjin, S.; Beibei, Y.; Guanyi, C. Hydrothermal carbonization of garden waste by pretreatment with anaerobic digestion to improve hydrohcar performance and energy recovery. Science of The TotalEnvironment,2022, 807,151014, https://doi.org/10.1016/j.scitotenv.2021.151014.

Fernandez, H.C.; Buffiere, P.; Bayard, R. Understanding the role of mechanical pretreatment before anaerobic digestion: Lab-scale investigations. Renewable Energy, 2022, 187 , 193-203, https://doi.org/10.1016/j.renene.2022.01.067.

Changmin, L.; Seunghwan, Kim.; Man H.P.;Young, S.Lee.; Sungho, L.; Junmo, Y. Valorization of petroleum refinery oil sludges via anaerobic co-digestion with food waste and swine manure. Journal of Environmental Management, 2022, 307 , 114562, https://doi.org/10.1016/j.jenvman.2022.114562.

Irnia, N.; Eka N.S.; Nurul, A.; Sri, S.; Timothy, D.H.; Barker, C. Application of ligninolytic bacteria to the enhancement of lignocellulose breakdown and methane production from oil palm empty fruit bunches (OPEFB). Bioresource Technology Reports, 2022, 17 , 100951, https://doi.org/10.1016/j.biteb.2022.100951.

Charles, R. ; Grace, N., Ijoma, T. ; Matambo, S. Elucidating Biodegradation Kinetics and Biomethane Potential Trends in Substrates Containing High Levels of Phytochemicals: The Case of Avocado Oil Processing By-products. Waste and Biomass Valorization, 2022, 269, https://doi.org/10.1007/s12649-021-01663-z.

Zwawi, M.; Algarni, M.; Bahadar, A.; Iqbal, H.; Sergio, C. Capareda, Muhammad Adnan Hanif, Adeel Waqas, Nazia Hossain, Muhammad Tahir Hussain Siddiqui, Sabzoi Nizamuddin, Asma Jamil. The Effects of Using Pretreated Cotton Gin Trash on the Production of Biogas from Anaerobic Co-Digestion with Cow Manure and Sludge. Energies, 2022, 15 (2) , 490, https://doi.org/10.3390/en15020490.

Qiang, L. ; Lingjuan, L. ; Xiangzhen, L. carbon feedstocks trigger a priming effect in anaerobic digestion: An insight into microbial mechanisms. Bioresource Technology, 2022, 344 , 126243, https://doi.org/10.1016/j.biortech.2021.126243.

Tawanda, K.; Xiaohua, X. A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. Bioresource.Technology, 2022, 344 ,126311. https://doi.org/10.1016/j.biortech.2021.126311

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Hassan asnaoui, Mohammed Khalis, Zouheir Amraoui , Lahcen Ait-Mlouk

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any article in the International Journal of Engineering and Applied Physics is retained by the author(s) under the Creative Commons license, which permits unrestricted use, distribution, and reproduction provided the original work is properly cited.

License agreement

Authors grant IJEAP a license to publish the article and identify IJEAP as the original publisher.

Authors also grant any third party the right to use, distribute and reproduce the article in any medium, provided the original work is properly cited.

Most read articles by the same author(s)

- Hassan asnaoui, M. KALIS, M.BOULAALAM, The Study of Simulation of RC, RL and RLC Circuits Using Matlab in Teaching , International Journal of Engineering and Applied Physics: Vol. 4 No. 2: May 2024